Boosting the Bottom Line with Drone Technology in Agriculture

- Jack Harris

- Oct 19, 2025

- 8 min read

Updated: Oct 20, 2025

Margins in farming have never been tighter. Rising input costs, unpredictable weather, and market volatility mean every decision counts.

As you can see from the photo of my younger, thinner self to the left, I’ve been using drones in agriculture for many years now. The drive and potential have always been there — but back in 2016, the tools and data processing often fell short of what we wanted to achieve.

Fast-forward to 2025, and drone technology has truly taken off. The question is no longer “Can we do it?” but “How do we use this data effectively — and how can it work alongside modern machinery?”

In this blog, we’ll look at the different ways drones can boost farm profits through improved efficiency, reduced inputs, and smarter field scouting — and how FieldCraft Technologies makes this practical and profitable for UK growers.

Why use Drone Technology?

Modern farming is about working smarter, not harder — and drones are one of the most effective tools helping farmers do exactly that. By providing a bird’s-eye view of your crops, drones make it easier to spot problems early, reduce costs, and improve yields. A relatively low cost of entry into drones also helps.

Basic RGB drones are substantially lower cost than multi-spec drones, which can offer more specific uses.

See What’s Really Happening in Your Fields Drone Technology In Agriculture

Walking every hectare simply isn’t practical, especially on large farms. Drones can quickly capture detailed aerial images showing crop health, weed pressure, pest damage, and variations in soil condition, giving you a complete, accurate picture of your crop performance — something that’s impossible to see from the ground.

Not all drone flights need to be super detailed and flown using specialist software. Sometimes one quick flight is all you need to get a good idea of field conditions.

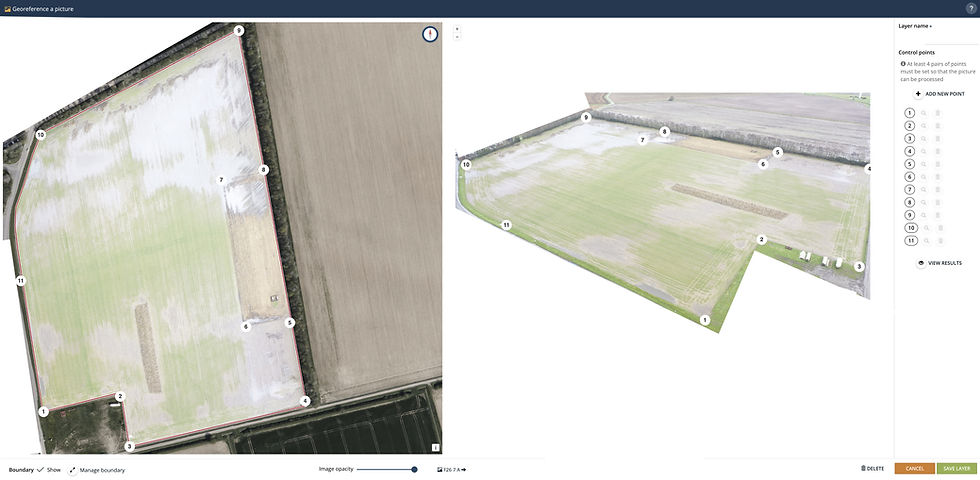

In platforms such as Omnia Digital Farming from Hutchinsons, one image can be stretched and transformed into a rapid scouting tool. Instead of spending hours processing and stitching data, you can get a usable overview of a field in minutes. Provide the software with some reference points, with a boundary, and Omnia stretches the image to fit the boundary.

While it's not ideal for spot spraying or variable rate maps, this quick method is excellent for scouting. In the example above, in a very wet year, the drone image was used to highlight issues with drainage. Once in Omnia, a simple layer was generated, and a manually drawn area was used to calculate the spring seed needed to fill in the failed crop areas.

Make Better, Data-Driven Decisions Drone Technology In Agriculture

High-resolution and multispectral imagery from drones can be processed into index maps that use specific light wavelengths to show variation in crop nutrients and plant health.

Plant counts and establishment maps can also be produced, helping you make smart management choices such as:

Where to apply fertiliser or sprays

Which areas need re-drilling

How to target pests or weeds precisely

When to irrigate or adjust inputs

The result? More precise decisions that boost efficiency and cut waste.

Fertiliser applications using Drones

Let’s look at a practical example — a field of winter wheat. A common fertiliser strategy might involve three splits across the growing crop.

1st Application – Flat Rate Drone Technology In Agriculture

A uniform rate to get the crop started and encourage early growth. Variable rate is rarely used at this stage as the crop is small, and we’re simply aiming to get things moving.

2nd Application – Variable Rate

This is where drone data becomes powerful. You can:

Apply more N to lower-biomass areas to encourage growth

Apply a maintenance rate on stronger areas

Or flip the strategy, giving stronger areas more to maximise potential yield

Background data, such as soil scans or yield maps, make these decisions even more precise.

You can treat fields as potential zones:

Poorer areas yielding ~5t/ha receive less N

High-potential areas (~10t/ha) receive more N

This ensures nutrient inputs are targeted where they’ll deliver the greatest return.

3rd Application – Variable Rate

For protein or milling spec, another variable-rate pass can fine-tune your strategy.

Remember, variable rate isn’t about evening up the field — it’s about optimising inputs where they’ll pay back most. Trying to drag poorer areas up to the field average usually wastes money.

Using the Right Sensors

For variable-rate N inputs, accuracy is everything. Multispectral drones use specific light bands (such as the Red Edge wavelength) that correlate directly to plant health and chlorophyll levels.

For instance, an NDRE (Normalised Difference Red Edge) index map might show values around 0.6 for healthy, high-biomass zones. With that data, you can adjust your standard N rate up or down accordingly, or cross-check with a handheld Yara N-Tester for precision.

Once these decisions are made, variable-rate maps are generated, showing savings and application efficiency.

In one example seen below, a drone-mapped wheat field achieved 5.42% savings in product use, just from one field.

This field has been flown with a multispectral drone, and the individual images stitched together to create a map showing poor areas in blue/yellow/red and better areas in purple.

The field can be zoned. The level of detail is up to the grower. Do you want 2 zones or 8?

In this example, it was decided to go for 6 zones. A standard rate for the field is 100kg/ha of product. (Work out your product rate required for N being applied)

At the bottom left, we have given a strategy for the application. In this example, we have chosen that where it sees a stronger zone, it will increase the product rate, and reduce it in a weaker zone. We have told the system we want to increase by up to a 50% rate in stronger zones and decrease by 20% in weaker zones. This can be decided by you.

Once your decisions have been made, the rates are applied, and you can see how much product is needed for the field, including savings where applicable, which in this case was 5.42% savings of product on this one field.

Relevant files are produced and sent to you to be used.

Now all of this sounds like a lot of work, but with FieldCraft Technologies UK Ltd, we will come and fly your fields with our Multispec RTK drone, process the data and return your variable rate files. Simply tell us your strategy and standard rate, and we can do the rest. No need to spend time with maps, we can handle that.

Get in touch at info@fieldcraft-tech.co.uk to discuss your variable-rate mapping needs

Weed Mapping using Drones

Reduce Input Costs and Boost Profitability

Every input that’s saved or used more efficiently adds to your bottom line. Every unnecessary spray can have a detrimental effect on yield — so targeting applications pays off.

While variable-rate fertiliser strategies improve efficiency, weed mapping and spot spraying can deliver even greater savings. With today’s AI-powered software, it’s easier than ever to turn your sprayer into a spot-spraying system.

At FieldCraft Technologies, we can offer Carbon Bee Smart Striker X, a revolution to spot-spraying technology. Spray green on brown or green on green in crops! Higher up-front costs and certain sprayer criteria often mean it might not be practical for every farm. The costs of the spot spraying system can usually be paid off by savings alone within 2-3 years or even quicker with grants, but even so, if it's not right for you, but you want to save money and inputs, what do you do?

Drones can do that!

Remember back in 2016 when I was using drones? Well, we were able to map weeds to an extent, but trying to get software or technology to make and process files was time-consuming and very hard. Often, the cost of the drones needed was over £10,000, and the software and time were also expensive, which meant it was a costly service. Drone Technology In Agriculture

Fast forward to 2025, and drones for mapping weeds are a lot lower cost (still expensive though!), and software is readily available to help identify and map weeds. Crucially, we can now get this data out of the clouds and into a sprayer with greater ease.

Carbon Bee Smart Striker X can identify weeds in the crop on the go and control the sprayer at the same time, meaning there is no need to collect data before spraying. Drones at this moment in time require a flight, processing of the data, which is usually large amounts and then export back out to the sprayer.

This means a little bit more time and planning is needed, but it means a defined prescription map can be generated, and the operator knows exactly what is needed in the tank.

Using a drone to map weeds and make spot spray solutions also means that sprayers which don't have individual nozzle control can be used, as the files exported to the sprayer will turn on the relevant sections. With individual nozzles, a very detailed spray can be achieved, leading to greater savings. That being said, a 7-section sprayer can also see some savings, just not as much as you'll be turning 7 nozzles on at a time vs just 1 or 2.

In the example below, a sugar beet field was flown with a drone, mapped for all weeds, and then another plan was created for plant counts and establishment. As we are over with the drone, we can also utilise the data captured for other applications too!

Total savings for this field were 92% of chemical use, easily paying for the flight costs.

Utilising the same flight with the drone, plant counts and an establishment map were created, allowing the grower to gauge early on in the season, potential yield loss and management plans for N and other inputs.

Drone mapping also offers the ability to map specific weeds and make plans for those if a specific chemical is needed or a glyphosate spray is wanted in a growing crop.

In this example, a field of carrots was flown. Using the same data from one flight, 2 plans were made. One for all weeds seen. The other is for a specific weed (amaranth) in the growing crop.

Scroll through the images to see the results; the all-weed spray saved the grower over 37% on their chemical bill, but the greatest savings were seen when targeting just the amaranth weed. In that case, the savings jumped to over 93% chemical savings.

Green on Brown spot spraying is achievable for stubble burn down, as well as green on green weed targeting in crops.

By flying the field and taking ground reference photos, we can ensure accurate modelling is completed to map weeds in your crops.

Interested? Why not send FieldCraft Technologies an email at info@fieldcraft-tech.co.uk to speak to us to find out more?

We will come fly your fields, process the data and get your files back as quickly as possible. Green on Green is possible, just discuss your needs and let us help you save some money.

Support Sustainability and Compliance

With growing environmental regulations and sustainability goals, drones help demonstrate responsible and targeted chemical use. Be more efficient with fewer tank fills needed and lower machinery hours.

Sustainability also comes back to the farm level. With massive savings to be achieved on some of the biggest bills on the farm, targeted weed control could really help the bottom line.

Why choose FieldCraft Technologies?

Nearly 10 years of experience in agricultural drone technology in the UK

Fully CAA-licensed and insured

Access to multiple data processing platforms for accurate, flexible outputs

Complete fly–process–deliver service — you tell us your goals, and we handle the rest

At FieldCraft Technologies UK Ltd, we combine expertise, experience, and technology to help UK farmers make smarter, more profitable decisions from the air.

Email us at info@fieldcraft-tech.co.uk to find out how we can help your business take flight.

Keep an eye out for more news from FieldCraft Technologies and drones!

Announcements to be made post Agritechnica about how you can access some of the most powerful drone mapping software available.

SALE NOW ON!! 10% off your purchase!

Valid until 01/12/2025